PSVisionBulider is a universal standard visual software tool platform independently developed by Porcheson Company. It has a simple and clear UI human-machine interface, covering various tool modules encapsulated by image algorithms such as positioning, presence/absence detection, defect detection, measurement, counting, geometry, recognition, etc., making it highly versatile and easy to operate.

Software features

A simple graphical UI interface that supports Chinese/English language switching. After simple training, users can complete software operations without the need for professional image and computer knowledge;

Over a hundred packaged image algorithm tool modules allow users to complete detection tasks without programming and drag and drop operations;

Rich algorithm tools and multiple data communication interfaces, providing customers with a set of software that is universal in various visual application scenarios and suitable for various industries;

Compatible with various domestic and foreign brands of gigabit networks and USB3.0 interface camera hot swappable access, compatible with supporting the Win7/Win10 operating system, users can easily choose relevant hardware to build a visual system;

Supports simultaneous access of 8 cameras and the creation/saving of 256 programs, meeting various complex multi-station detection and fast switching needs;

Framework

Positioning module

The system is embedded with an intelligent shape recognition engine, which can recognize common basic geometric shapes

For complex shapes, the system can perform template learning training to achieve recognition of complex shapes

Multi point mapping calibration and calibration board calibration, which can convert image pixels into world coordinates, etc

RS232/485 communication and network communication (server) with standard protocols make communication simpler

Positioning tool |

|

|

Geometric Tools |

| |

Coordinate calibration |

| Using hand eye calibration or anchor point calibration methods to convert image coordinates into robot coordinates |

Data Communication |

| You can choose different communication modes according to your needs, and then select the data to be sent. The data can be arranged freely and the format of the sent data can be adjusted. |

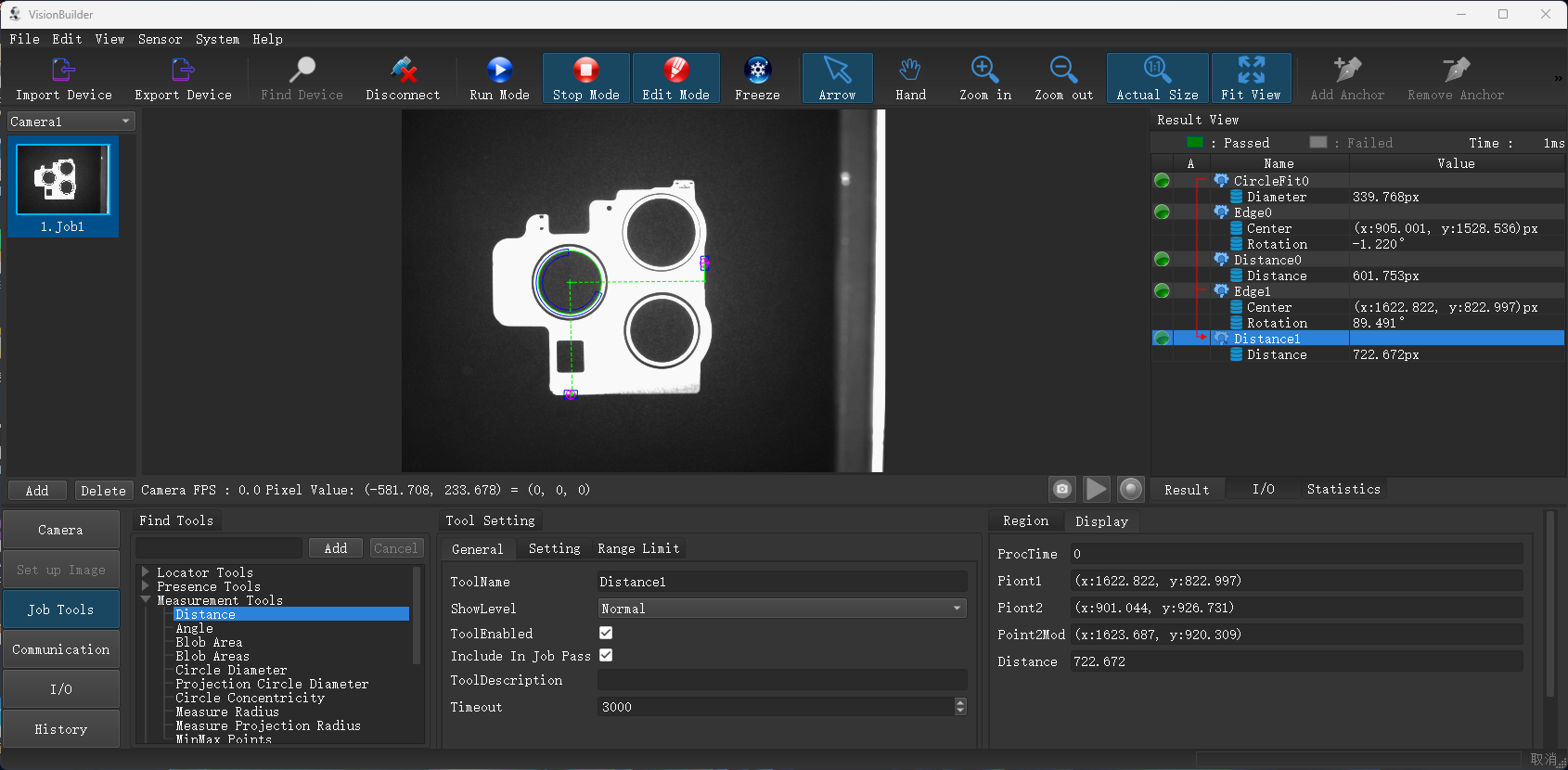

Measuring module

LPSVisionBulider machine vision measurement software is suitable for online and offline size measurement of products in various industries, with sub pixel measurement accuracy

Dozens of geometric algorithm operations and more than ten measurement tools make measurement simple and powerful

Dragging and dropping between various tools can achieve fast numerical, result, and image linking.

Calibration of circular, square, checkerboard and other calibration boards, and scale calibration

Measurement |

|

|

Count tool |

| |

Measurement calibration |

| Circle or checkerboard calibration, converting image pixels into actual unit values (mm) |

Check module

Detect organizational errors, surface defects, product damage, missing, and other special features

Roundness detection, trajectory detection, straight edge burr detection, etc

Is there any testing tool available |

|

|

| Defect detection tools |

| Customized specialized defect detection tools based on industry products. |

Identification module

Text reading, reading and verifying letters, numbers, characters, etc. on products or components.

Read one-dimensional barcode, QR code, and postal code.

Read data communication output, RS232/RS485, TCP/IP, I/O output.

Identification tools |

|

|

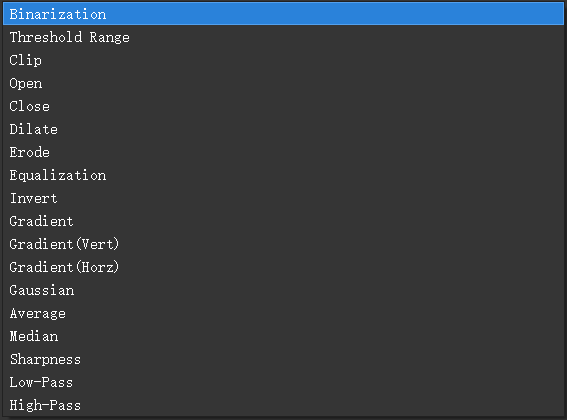

Professional tool module

Image filtering tools |  | In image preprocessing, a series of preprocessing algorithms can be added to gradually preprocess the image. The modules selected by subsequent users are executed on the preprocessed images. |

Running control tools |

| Logical control of the sequential processing of tools |

Mathematics&Character Tools |

| Mathematically calculate the results obtained from the measurement module to generate new values, or compare the contents of two strings to see if they are consistent. Fixed strings can be set, and so on |

Supports multiple camera requirements

PSVisionBulider machine vision software can capture images based on hundreds of camera platforms. Currently, it supports MindVision GIGE/USB series cameras, Basler GIGE/USB series cameras, AVT GIGE/USB series cameras, and Baojixin GIGE/USB series cameras.

Advantages and characteristics

Intelligent engineering management - capable of simultaneously detecting different models of products on the same production line.

High degree of freedom communication method - choose one of the communication methods according to customer needs.

Compatibility at the SDK level - the system is directly equipped with the manufacturer's original driver package.

Intelligent remote monitoring - can monitor all detection product lines within the local area network.

Data translation module - capable of "translating" input and output signals, supporting user-defined rules

Local and FTP data storage - Detection data can be stored locally or transmitted to other servers through FTP.

Other auxiliary functions - including intelligent parameter determination, logic detection, system operation logs, and historical recording.

粤公网安备 44030602006806号

粤公网安备 44030602006806号